The DMAIC Methodology

The DMAIC cycle is the driving force behind Six Sigma process improvement projects. This methodology is use when improving existing processes. Use DMADV for new processes.

DMAIC is an acronym for the 5 required phases of a Six Sigma project.

Define

The Define phase is where the team begins the journey into the problem at hand. Initially the champion determines if the problem warrants using six sigma methodology; it is possible that the issue can be resolved using 8D.

The key deliverable for this phase of the DMAIC process is the project charter. The project charter document is a living document throughout the life of the project, that is, it is expected that the project charter may be revised from time to time during the project lifetime.

Important aspects of the project charter are as follows:

- The Business Case- A well-written business case will explain to top management the importance of the project. It could detail the costs incurred to date for this problem, describe the consequences of taking no action, correlate the project to current business objectives, and specify the potential impact of the project in monetary values

- The Problem Statement- The purpose of the problem statement is to clearly describe the problem at hand and to provide important details of the problem's impact to your organization. More information on creating a problem statement can be found by clicking on the link.

- The Goal Statement- This element defines the expected results from the project. The results should include information regarding project completion time line, savings expected, improvement objectives and how they will be measured, and how reaching this goal will influence any Critical to Quality (CTQ) elements of your project.

- Project Scope- The project scope itemizes the project boundaries. It is imperative that the beginning and ending process steps are identified. This will help keep your team focused and help prevent "scope-creep."

- Cost of Poor Quality- The COPQ metric states in financial terms how much the problem had cost your company over a given time period. Read our COPQ Case Study.

Measure

The measure phase is the second phase of the DMAIC process. The objective of this phase is to garner as much information from the current process. The improvement team needs to know exactly how the process operates, and is not concerned with how to improve the process at this time.

The important tasks in the measure phase are the creation of a detailed process map, collection of baseline data, and finally summarizing the collected data. In most projects, the process map will be completed first.

The process map provides a visual representation of the process under investigation. It can also provide additional awareness of process inefficiencies such as, cycle times, bottlenecks or identify non-value added process requirements. The process map may also show where data can be collected.

Two critical aspects of process mapping are:

- Draw the process map exactly as it exists. If you create the map at your desk, you are likely to miss key elements of the process, such as any redundant work or rework loops.

- Always walk the process to validate the correctness of your process map.

Create a data collection plan

In the define phase your team developed a list of CTQ characteristics. Data to be collected should relate both to the problem statement and what the customer considers to be critical to quality. This data will be used both as baseline data for your improvement efforts and to calculate the current state process sigma.

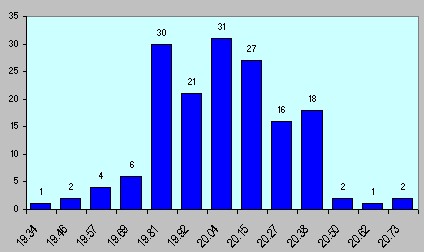

The data will then be graphed or charted to obtain a visual representation of the data. If the team was collecting error data, then a Pareto Chart would be a likely graphical choice to help prioritize the team's efforts. Or perhaps a trend chart is needed to show how the process reacts over time. Histograms are another excellent way to observe your process data.

Another widely utilized tool in the measure phase is the Control Chart. The control chart is both a visual depiction of a process and a statistical tool that shows which elements of variation are common cause (natural variation within the process) and special cause (variation caused by an external factor).

Current state process sigma is then calculated from the collected data. This metric allows a comparison between different processes and illuminates the difference between the current state and the improved state of the process.

Analyze

The third phase of the DMAIC process is the analyze phase, where the team sets out to identify the root cause or causes of the problem being studied. But unlike other simpler problem solving strategies, DMAIC requires that the root cause be validated by data.

Several root cause analysis methods are available for use in the analyze phase, including Brainstorming, 5 Whys, and the Fishbone Diagram, also known as a Cause and Effect Diagram or an Ishawaka Diagram.

As with most root cause tools, the team should utilize the process map, the collected process data and other knowledge accumulated during the define and measure phases to help them arrive at the root cause.

Validating the Root Cause

The true power of the analyze phase of the DMAIC process is the statistical analysis that is conducted. Six Sigma belts are looking for statistically significant events upon which to act. It's this higher level of analysis that sets Six Sigma apart from lower level problem solving strategies.

Techniques such as ANOVA (Analysis of Variance), Correlation Analysis, Scatterplots, and Chi Square analysis are commonly used to validate potential root causes.

Improve

The objective of the DMAIC improve phase is to determine a solution to the problem at hand. Brainstorming is commonly used to generate an abundance of potential solutions. It is a great idea to include people who perform the process regularly. Their input to solution creation can be invaluable, plus they may also provide the best potential solution ideas because of their process knowledge. In fact, it's a great idea to communicate to those involved in the process on a regular basis throughout the improvement project.

Some prefer to conduct free-form brainstorming sessions, but with the addition of some simple rules for brainstorming a highly successful session will be conducted, and you'll probably have some fun in the process. Also, review our guidelines for effective brainstorming.

Selecting the Best Solution

Keep in mind that the term best does not mean the same thing to all people. What the team should strive to find is the best overall solution. A solution criteria list is another good tool to assist in selecting the best solution. An example is shown below:

- Time

- Time to implement the solution

- Cycle time reduction

- Cost

- Cost to implement

- Process cost reduction

- Misc

- Defect reduction

- Simplify the process

The team then evaluates the list of potential solutions against the list of criteria. Not only does this speed up the process of evaluation, it also gives all team members the same basis for choosing the best possible solution.

Validating the Selected Solution

Prior to implementation, the team must be assured that the selected solution actually works... yes, imagine that, let's be certain before we fully implement. Pilot programs, computer simuilations, segmented implementation are all possibilities at this point. The team also creates a future state process map as part of the improve phase. This is done so that after implementation, the team can once again walk the process to ensure the implementation was accomplished correctly.

Control

The final DMAIC phase is the control phase; its objective, simply put, is to sustain the gains that were achieved as a result of the improve phase. The team should create a plan that details the steps to be taken during the control phase. These might include:

- Review and update the process map

- Update any affected work instructions

- Develop training that describes the newly implemented methods

- Determine new metrics to verify the effectiveness of new process

- Determine if the process changes can be effectively implemented in other processes

Once the control phase tasks have been completed, it's time to transfer ownership of the new process to the original process owner. The team should discuss with the facilitator any new potential project ideas that may have come up during the course of the improvement project.

All that's left is to celebrate the team's success. The scale of the celebration is up to each individual company, but in order to create a robust improvement environment, recognition of the team's efforts should take place. Some examples of Six Sigma gifts from Successories can be found here. They pay for themselves by enhancing employee morale!

One last word of caution- The DMAIC methodology works, companies have saved hundreds of millions of dollars using it. Do not be tempted to solve everything at once, do not work outside of your project scope, and do not skip steps in the DMAIC process. Trust it to work.... and it will work for you.